The radial forging machine allows the manufacture of bars in the diameter from 100 to 500 mm and length of up to 15 meters with an accuracy of ±2 mm.

In order to achieve higher flexibility of manufacture and faster delivery, we maintain a stock of input materials, in particular ingots and billets for Oil&Gas applications, tool steels and materials for the machinery industry.

We can also offer storing the customer's materials if need be.

Our company owns an open die fonrging machine with the power of 16 MN (1600 tonnes) fitted with a manipulator with the capacity of 12 tonnes. In addition to the bars and billets, this machine can also produce shaped and hollow forgings. Thanks to the powerful furnaces, the capacity can reach up to 1,000 tonnes a month.

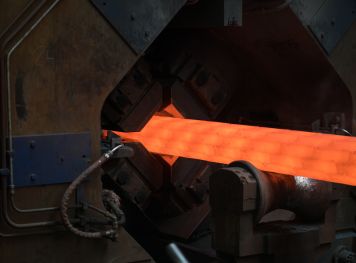

The heart of the company is a hi-tech high-speed forging press with the force of 18 MN (1,800 tonnes) and the speed of up to 220 punches per minute.

The rotary forging in combination with the traditional forging give us a great deal of flexibility in the area of the product portfolio. The high-speed forging press is suitable for the production of special alloys as well as standard steels.

The heat treatment facility is one of the most modern in the world. It is a complex of eight furnaces, a manipulator and hardening tanks – water, polymer. The heat treatment meets the strictest standards.

The workplace is certified for Oil&Gas applications (API 6A Annex M rev. 21) as well as the aviation industry (AMS 2750E).

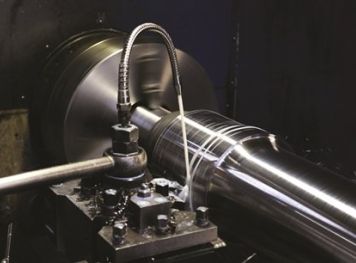

We rough standard products to the roughness of up to Ra 1.6.

We also provide machining on lathes and milling machines including drilling and finishing.

We cooperate on surface treatments to achieve higher mechanical properties – nitriding, hard surfacing.

One of the most important phases in the manufacture is nondestructive testing. We have an expert NDT team who have become one of the most demanded teams in Central Europe under the management of the top-qualified level III specialists.

We deliver products mechanically and metallographically tested according to the standards or the customer's specification. We use the local Vítkovice Testing Center s.r.o. and, if need be, cooperate with other testing centres in Europe and the USA.

We ship the products by land and rail and load them by crane or forklift. We ship containers, which travel to the seafaring vessels, as well as special loads.

The shipping department is open Non - Fri 6:00 - 13:00 hours.

We have more than 190-year tradition in the manufacture and processing of steel.

With our unique equipment, we can produce and process a broad portfolio of materials, which are used in the most demanding industrial applications.

We process stainless steel for leading manufacturers in various branches of industry

MorePlease specify the nature of your question.

We will contact you to specify details and the available possibilities.